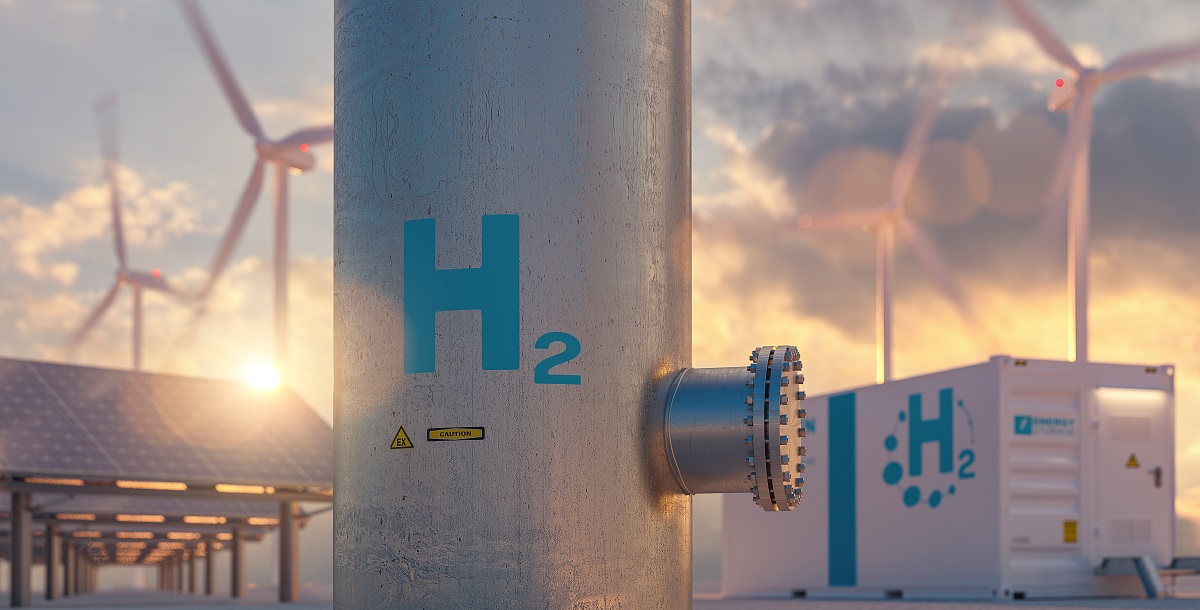

Breakthrough in carbon-neutral hydrogen production

A new way of creating hydrogen, which eliminates direct CO₂ emissions, has been developed by teams of scientists from Wales and China.

The process reacts hydrogen-rich and sustainably sourced bioethanol taken from agricultural waste with water at just 270°C using a new catalyst made of platinum and iridium to extract hydrogen, without releasing any carbon dioxide. .

Traditional methods, which operate at temperatures between 400-600°C, are energy-intensive and generate large amounts of CO₂. Using the catalyst shifts the chemical reaction to create hydrogen without releasing carbon dioxide as a biproduct.

Instead, the process produces high-value acetic acid, an organic liquid found in vinegar and used in food preservation, household cleaning products, manufacturing and medicine, with an annual global consumption exceeding 15 million tons.

Peking and Cardiff Universities

The researchers from Peking University and Cardiff University, say the study represents a boost in de-fossilising the chemical industry, by replacing fossil feedstocks used in making chemicals with an alternative carbon source.

Their findings, published in Science, mark a step-change in carbon-neutral hydrogen production, and establish a circular economy model for co-producing hydrogen and high-value chemicals from biomass.

Co-author Graham Hutchings, Regius Professor of Chemistry at Cardiff University, said: “Finding sustainable ways of creating the products we need for everyday life and to meet net zero ambitions for the future is a key challenge facing the chemical industry.

“Hydrogen is widely regarded as one way of achieving these ambitions because it is made from natural gas. However, it is extremely energy intensive and, of course, when created through traditional methods, it produces large amounts of carbon dioxide limiting its environmental benefits.

“Our study offers a new pathway which allows for high-yield hydrogen production without the CO2 emissions.”

Fossil fuels

According to the International Energy Agency (IEA), approximately 96% of global hydrogen production still relies on fossil fuels, emitting 9-12 tons of CO₂ per ton of hydrogen.

The team’s breakthrough builds on more than a decade of collaborative research experience on metal-carbide catalysts for hydrogen production by the international group.

Lead author Professor Ding Ma of Peking University, said: “This innovative catalytic technology holds considerable promise for advancing the green hydrogen economy and supporting global carbon neutrality goals.

“Furthermore, the co-generation of acetic acid, a chemical with substantial industrial applications, enhances the technology’s economic viability and sustainability.”

Professor Hutchings, who last year chaired a policy briefing for the Royal Society on defossilising the chemical industry, added: “By co-creating the two chemicals in tandem, the innovation could serve as a low-carbon alternative for industries such as acetate fibre manufacturing and pharmaceutical intermediates going forward.”

Their paper, ‘Thermal catalytic reforming for hydrogen production with zero CO₂ emission’ is published in the journal Science.

Support our Nation today

For the price of a cup of coffee a month you can help us create an independent, not-for-profit, national news service for the people of Wales, by the people of Wales.

Surely the best method for producing hydrogen is to use “spare” electricity from turbines currently forced to stop producing when no-one needs their power to turn water into hydrogen and oxygen like we all did in school.

Unfortunately, At present, by the time you’ve electrolized water, compressed and liquified the Hydrogen the efficiency is 56 – 73%.

Current Hydrogen Fuel Cell efficiency (turning it back into DC electricity) is around 40 – 60%, not including any losses when converting to AC for injection back into the grid.

This gives us at best 60% of 73% = 43% overall for the full cycle.

At the moment a variety of Liquid flow batteries can do rather better than this and are much safer, more environmentaly friendly and much less likely to burst into inextinguishable flames than current Lithium-Ion cells.

That’s absolutely fine when the alternative is to have turbines switched off because no-one wants their juice at 3am.

Why are you referring to efficiency in such a narrow way? How “efficient” is it to let 100% of underutilised capacity go completely to waste, when you could get some return? Once renewable capacity reaches saturation at peak demand, there will be lots of excess capacity, off-peak, looking for a use. Also your efficiency figure, which I presume is based on loss of thermal value, ignores the fact that hydrogen is not the only product of electrolysis. There will also be oxygen, which has a value to industry, and will offset part of the cost. Another advantage of hydrogen is… Read more »