Making tracks: Taffs Well

Jon Gower visits Transport for Wales’ shiny new South Wales Metro depot, which was officially opened on Friday.

One of first things that strikes you about the capacious building – where a fleet of 36 new tram-trains will be maintained – isn’t simply the size of the place, it’s the cleanliness. To say it’s spick and span doesn’t come close.

It’s clearly a source of considerable satisfaction for depot manager Phil Bishop, who hails from nearby Pontypridd: ‘When we walk around now, you’ll see it’s clean, neat and tidy, everything’s got its place. For me, that definitely shows me staff ownership.’ As we speak, a black smear on the ground is brushed swiftly away by a passing cleaner.

As a boy, working on the railways wasn’t Phil’s dream job. He wanted to play upfront for Liverpool but also ‘wanted to be in engineering and it’s turned out great now.’ Which might not currently apply to Liverpool FC, given their dire season so far.

The small football stadium-sized depot was constructed on a 5-hectare site which used to be home to South Wales Forgemasters. Work started here in earnest in 2020 after the company’s two huge sheds had duly been demolished and the ground cleared.

Phil and his co-workers subsequently helped engineer the transformation of bare earth to train garage: ‘When I started here, this place was ground zero, it was nothing. Now there’s just over 400 people allocated to this depot – train crew, maintenance staff, and all the ancillary people as well. I think’s that pretty much the same staffing number as when Forgemasters was in its heyday, so that’s good. It’s probably one of the most modern depots in the UK, in Europe even.’

Transport for Wales has been keen to avail themselves of the skills of many small companies as Phil explains: ‘There are lots of little local workshops which manufacture this, that and the other. Rather than us getting bits and bobs we need for the depot from all the big names, I was really keen on just walking over the road and knocking on someone’s door and saying, can you make this? And I can pretty much guarantee that’s happened right the way up through the network.’

Phil’s team has contributed a legion of their own bright ideas to the workplace, from innovations in storage and tooling through to choosing the paint colour for the floor.

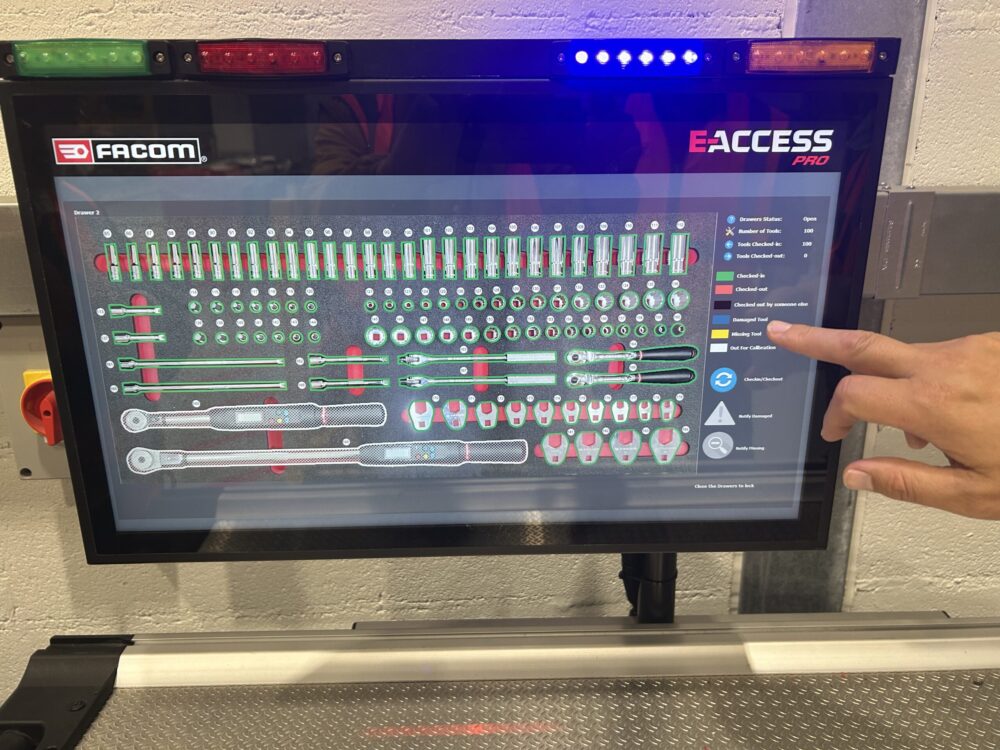

With real enthusiasm he singles out the touch-screen, computerised toolboxes for particular praise as they ensure the right tool is always to hand. ‘They can track who carried out any particular work on any particular train’ adding ‘if you’re not qualified you even can’t get into this toolbox and use any of them.’

Such traceability is especially important should something go awry.

Other Taffs Well innovations include vibration watches which monitor how long someone’s been using a tool, such as an orbital sander, advising the user when it’s time to take a break. This helps avoid occupational health hazards such as miners’ white finger, a condition suffered by colliers after wielding a drill for too long. Safety and efficiency clearly go glove in hand in the depot.

Phil cheerfully avers that the workforce at the Taffs Well depot is a happy one: ‘The guys are always smiling and happy, though whether they just smile when I’m there and frown once I’m gone, I don’t know. But the culture is really good here, really strong.’

I duly meet three of his colleagues who do indeed smile, with no obvious signs of doing so under duress.

Max Normandale is a performance technician at Taffs Well. He came here after working on trains for Hitachi and being a mechanic at BMW. ‘So I’ll be working on fault finding and rectification on the 308 fleet, not on the track but actually on the trains themselves, fixing any electronic faults or mechanical faults that might arise during the day, I’ll try and rectify those so that the trains can then get put back out into service.’

Having worked on an automobile brand that is a byword for quality and excellence how does Max think these new trains pass muster? ‘We haven’t actually had the luxury of seeing them out in service yet. It’s all brand new, electrified, so a lot cleaner and greener and, yeah, it should be a much-improved service.’

Shaun Scott is the maintenance team leader and is a relative newcomer to TFW, having started in August of this year. Shaun previously worked for the Cardiff-based Pullman Rail company, which overhauled and refurbished trains and is now owned by Transport for Wales.

Nervous

Is this a nervous time for Shaun and his colleagues as the clock ticks down to the opening up the South Wales Metro? ‘It’s nervous in the sense of obviously not having worked on these units before, but then obviously the team here is a confident team and I imagine any sort of issues that do arise we’ll deal with.’

Tim Gibbs combines roles as a maintenance tech and train driver, although he doesn’t travel very far in the cab. ‘We just drive on the depot. We don’t drive mainline. We also do the general day-to-day fixing and servicing of the trains.’ Tim is aware that they haven’t amassed the full fleet as yet but sees them being delivered quite regularly, so believes they should reach the full complement of 36 trains before too long.

He spends a good deal of his time moving trains around the depot, like a game of outsize chess: ‘We’re constantly moving. Just to get one train out, there could be two parked behind it, so there’s a lot of shifting around the yard to get to one to bring it in for a check.’

Once the trains have been moved into place it’s often time for some super-heavy lifting as depot manager Phil Bishop explains: ‘We’ve got really big lifting jacks, so it’s basically like taking your train to Kwik Fit, then lifting it up in the air. So there are four jacks one side of the train, four to the other side. They’re synchronized as well, so you plug them all in, they synchronize together and it lifts the train up in one go.’ They can also change the window glass weighting a ton and a half using vacuum suction cups. He makes it sound easy, especially given the weight of a train which can carry over 250 passengers.

The engineer in Phil finds plenty to admire about how the actual tram-train moves along: ‘It’s literally just a motor which drives like a Tesla car but on rails. There’s a lot less to maintain on it. Which means there’s a lot less that can go wrong, which means the train is better, more reliable, which means it stays out in service and serves the passengers for longer and better than the old diesel type trains used to. And they’re a lot cleaner as well.’

As Phil attests, the top speed for the trains is ‘limited to 60 mile an hour because that’s what the infrastructure dictates’ but the braking fully matches it, being able to pretty much ‘stop on a sixpence’ due to an electromagnetic system which can lock the train onto the tracks.

Admiring the serried ranks of stainless steel, Class 398 tram trains parked outside the depot, Transport for Wales Head of Media James Williams anticipates how ‘These will all run on the Metro. If you look back to, say, seven years ago, we’ve gone from having one of the oldest fleets, when we had 30 -year -old Pacers which were leaking, overcrowded, in terrible condition, to having these tram trains, which are electrified, probably the most modern fleet in Europe.’

When I suggest we might actually be looking at the future James agrees with avidity. ‘It is the future,’ he confirms.

The birth of a transport system dubbed the ‘Welsh Tube’ is most certainly an innovative prospect. And as the motto of South Wales Forgemasters, whose Garth Works made way for the depot had it: ‘As long as this World lasts, there will always be a new way of doing things.’

Jon Gower is Transport for Wales’ writer-in-residence. He will be travelling the breadth and length of the country over the course of a year, reporting on his travels and gathering material for The Great Book of Wales, to be published by the H’mm Foundation.

Support our Nation today

For the price of a cup of coffee a month you can help us create an independent, not-for-profit, national news service for the people of Wales, by the people of Wales.

Like Jon Gower, I was impressed with the £100 million TFW Metro depot at Taffs Well when I had the opportunity to visit as a local resident a year ago, in November 2024. It happened to be the day when TFW took ownership of the site from the contractors. Impressive Class 398 tram-trains were already parked in the depot and we were told they would be entering service about now (end of 2025). According to a report in Global Railway Review in March 2023, they were due to enter service in 2024. However, the latest mailing to local residents says: ‘Starting in… Read more »

Pacers disappeared in 2021.

Excellent article…I was there last week for the “opening”. It’s a very impressive achievement thanks to Welsh Gov and TfW. Looking forward to full Metro operations (so double frequency and reduced journey times) ..probably back end of 2026 early 2027??

Over priced, way behind time unneeded nonsense. The existing trains were coming to the end of their lives, Buy new trains. Two car 197s good buy. standard train on every route in Wales. As in Norther Ireland economies of scale and standardisation. The Valleys do not have the number of passengers to justify electrification. £750 million spent on dreamers ideas. Rhelford Elifant Gwyn!

That’s a pretty ill informed comment completely lacking awareness of demographic reality of CVL network (ps same 800m catchment population as Newcastle metro which is over 30m pax)